半導體 (Semiconductor)

解決方案與軟體

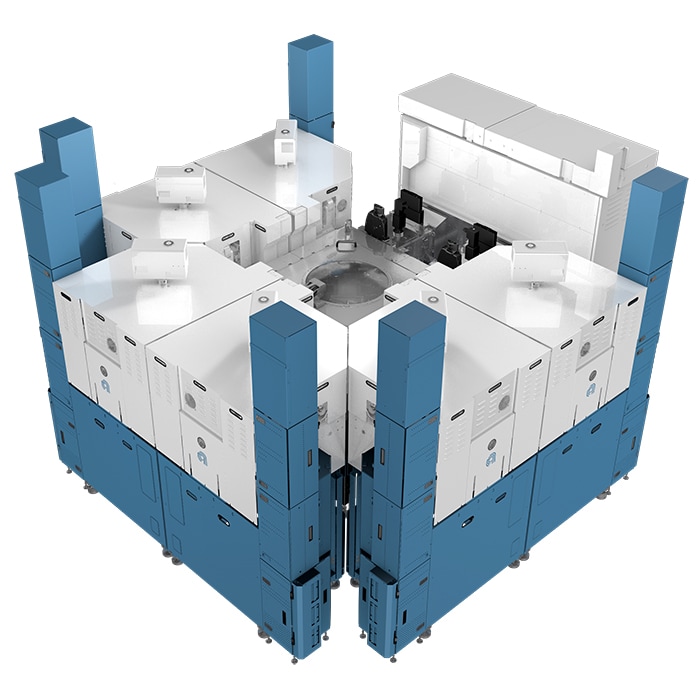

Centris Spectral 鉬原子層沉積系統

隨著 AI 與高效能運算持續加速發展,先進邏輯設計正快速導入環繞式閘極(GAA)電晶體架構。然而,在元件與上層佈線的介面上面臨關鍵的電阻瓶頸。這些介面上的奈米尺度接點,會對整體晶片效能和能源效率產生顯著影響。應材的Centris™ Spectral™ 鉬原子層沉積系統透過鉬沉積技術直接應對此項挑戰。鉬在極端微縮條件下仍能維持優異的電子傳輸表現,進而實現更快速、更具能源效率的裝置。

在先進製程節點中,隨著尺寸持續微縮,傳統接點材料的電阻隨之升高,效能表現也逐漸受限。Spectral 鉬原子層沉積系統透過原子級的精準控制,自下而上沉積單晶鉬,成功克服這些限制。憑藉應材在選擇性材料製程領域累積數十年的技術領導地位,此方法得以在維持良好導電性的同時,實現更小尺寸的接點結構。其結果是,與業界基準選擇性鎢解決方案相比,關鍵接點電阻再降低 15%,顯著提升新一代邏輯設計的效能與能效。

隨著元件架構持續演進至環繞式閘極、互補式場效電晶體(CFET),並邁向高度的 3D 整合,接點工程將在延續效能提升上扮演更關鍵的角色。Centris Spectral原子層沉積平台在設計之初即以前瞻需求為考量,提供一個能夠延伸支援未來先進製程節點與新型元件架構的基礎。。

應材Centris Spectral 鉬原子層沉積系統

- 1 / 4

- 2 / 4

- 3 / 4

- 4 / 4