エコ・アドバンテージ・ポートフォリオの拡大

アプライド マテリアルズは、お客様の事業の持続可能性を向上させるため、より多くのファブおよびサブファブの技術とサービスを継続的に開発しています

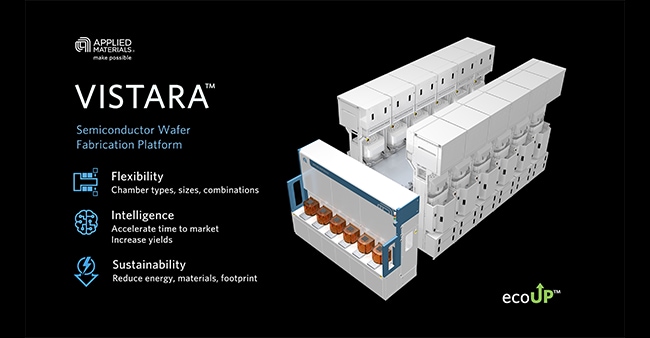

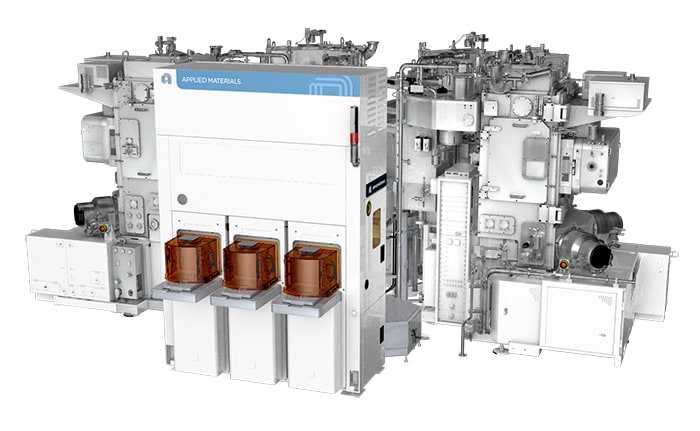

Vistara™ Semiconductorウェーハ製造プラットフォーム

Vistaraは当社初の専用プラットフォームで、より多くの種類とサイズのチャンバーを使用する統合材料ソリューションレシピをサポートするように設計されています。1つのツール内で複数のプロセスステップを組み合わせて共同最適化し、プラットフォームのエネルギー消費を推定35%削減し、エッチングアプリケーションの化学フットプリントを約30%削減します。

Centura™ Sculpta™ パターン形成システム

Centura Sculptaシステムは、ウェーハプロセスフローからEUVマスク層全体を排除する業界初のパターニング技術を特徴としています。この革新的なシステムにより、ウェーハあたり15kWh以上のエネルギー節約、ウェーハあたり0.34kg以上のCO2 換算のGHG排出量の直接削減、ウェーハあたり約15リットルの水の節約が可能になります。

EcoTwin™ エコ効率ソフトウェア

EcoTwinは、チップメーカーがファブのエネルギー効率と化学効率を最適化できるように、レシピとオペレーションを監視およびモデル化できるデジタルツインプラットフォームです。EcoTwinソフトウェアツールは、ファブとサブファブの両方からカーボンフットプリントと関連する消費パラメータの詳細なレポートを自動的に生成し、顧客が消費を削減する機会を特定するのに役立ちます。

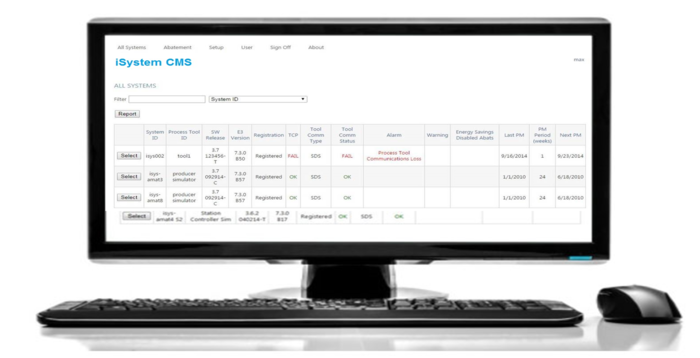

iSystemコントローラー

お客さまであるTSMCと共同で開発したiSystemコントローラーは、半導体製造ツールの操作による電力使用量の測定を自動化し、基準値に対する実際のエネルギー使用量を測定します。iSystem コントローラーは、他の環境要因の中でも特に継続的な温室効果ガス排出量のレポートを提供し、お客様がエネルギー関連コストを約 20% 削減するのに役立ちます。

エアリス™ G型

Aeris-Gは、実際のプロセスガス量を処理することにより、より少ないエネルギーを使用するプレポンププラズマ除害ソリューションです。各チャンバーのポンプ設置面積内に設置できます。新しいツールの設置では、サブファブのスペースを節約し、ユーティリティと排気の接続を減らし、設置コストを最小限に抑えながら、温室効果ガスの削減効率を向上させます。

ECOサービス

Applied Global Servicesが提供するサービスで、多数のプロセスツールとサブファブリソースが、環境効率の高いハードウェア、ソフトウェア、モノのインターネット(IoT)センサーに接続されています。このサービスは、お客様が電力とユーティリティの消費量と炭素排出量を測定、最適化、削減、監視するのに役立ちます。