Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

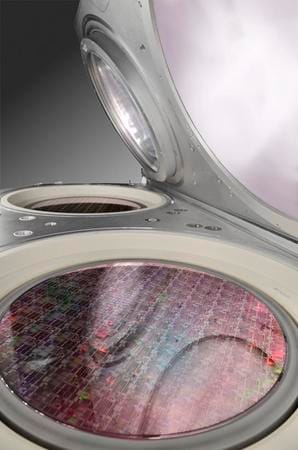

Producer® Nanocure® 3 UV Cure

The Applied Producer Nanocure 3 is designed to work with the Applied Producer Black Diamond® 3 deposition system to extend Applied’s leadership in nano-porous low-κ dielectric technology to enable the scaling of advanced interconnects to 28nm and below.

Black Diamond II nano-porous low-k film is the industry standard for the 45/32nm copper/low-k interconnects, with a k-value of approximately 2.5. Its predecessor, Black Diamond (k~3.0), is the industry-standard for the 90/65nm nodes. Creating nano-porous low-k film is a two-step process consisting of PECVD deposition of an organosilicate glass “backbone” and a thermally labile organic phase, followed by an ultraviolet (UV) cure that removes the labile phase—thereby inducing porosity—and restructures and strengthens the remaining silicon-oxide matrix to form the final nano-porous film. Small average pore size and tight pore size distribution eliminate the need for pore sealing.

Russ Perry explores Applied's breakthroughs in low-k dielectric technology.

The next-generation Black Diamond 3 film extends this industry-leading technology to ultra-low-k (ULK) film (k~2.2) for scaling to 22nm and below and improving device speed. It also imparts the mechanical strength (hardness and elasticity) required by emerging advanced packaging schemes. The film exhibits excellent moisture resistance, stable k-value after etch and photoresist removal, and superior mechanical strength.

This two-step deposition and cure process provides up to twice the mechanical strength of Applied’s successful second generation Black Diamond film – reducing device variability and boosting chip yield.

For more technical information regarding the Black Diamond 3 process, please visit the Producer Black Diamond PECVD page.