Producer® Black Diamond® PECVD

Applied Producer Black Diamond 3 extends Applied’s leadership in nano-porous low-k dielectric technology to enable the scaling of advanced interconnects to 28nm and below.

The Black Diamond II nano-porous low-k film is the industry standard for the 45/32nm copper/low-k interconnects, with a k-value of approximately 2.5. Its predecessor, Black Diamond (k~3.0), is the industry-standard for the 90/65nm nodes. Creating nano-porous low-k film is a two-step process consisting of PECVD deposition of an organosilicate glass “backbone” and a thermally labile organic phase, followed by an ultraviolet (UV) cure that removes the labile phase—thereby inducing porosity—and restructures and strengthens the remaining silicon-oxide matrix to form the final nano-porous film. Small average pore size and tight pore size distribution eliminate the need for pore sealing.

The Producer Black Diamond 3 system is designed to work with the Applied Producer Nanocure™ 3 UV curing system. The Nanocure 3 system employs a high-intensity UV source to stabilize and densify the Black Diamond 3 film to provide optimum mechanical and optical properties. This two-step deposition and cure process provides up to twice the mechanical strength of Applied’s successful second generation Black Diamond film – reducing device variability and boosting chip yield.

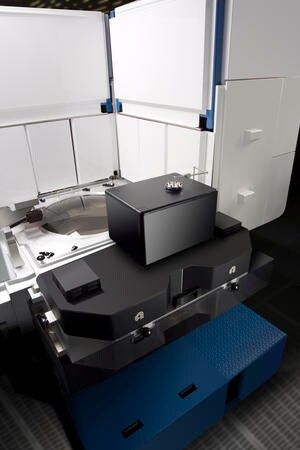

The Black Diamond 3 film is deposited using the production-proven, high-throughput Producer GT platform.

- 1 / 2

- 2 / 2