Applied Producer® XP Precision® Draco™ CVD

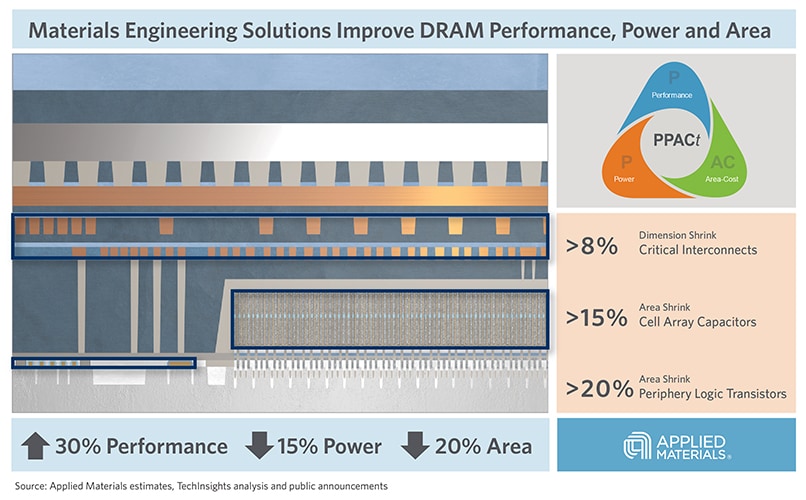

Today’s global digital transformation is driving the need for lower-cost, higher-density DRAM chips, particularly for data center servers. However, physical design limitations are restricting DRAM scaling from keeping pace with burgeoning memory demands of AI, 5G, the Internet of Things and other data-intensive computing applications.

The Applied Producer XP Precision Draco hard mask addresses one of the key limitations: DRAM storage capacitor scaling.

The capacitor is an ultra-small structure about 30nm in diameter. Its capacitance is proportional to its volume. As the capacitor diameter shrinks with scaling, the aspect ratio increases to preserve capacitance. But high-energy ions etching the ever-deeper capacitor holes also etch the hard mask. The higher the aspect ratio, the greater the risk that the hard mask will be eroded before the capacitor hole is fully formed, thus ruining the device.

The Draco hard mask resolves this issue with a new material whose selectivity is more than 30 percent higher than conventional DRAM capacitor hard masks. It enables deposition of a 30 percent thinner hard mask, thus decreasing the capacitor’s aspect ratio and easing the difficulty of the etch process.

The Draco hard mask is co-optimized with Applied’s Centris Sym3 Y etch system, which has been specially adapted to etch the new material, enhancing yields through 50 percent improvement in local CD uniformity and 100X reduction in bridge defects (shorts).