Products & Technologies

Products & Technologies

Services

Resources

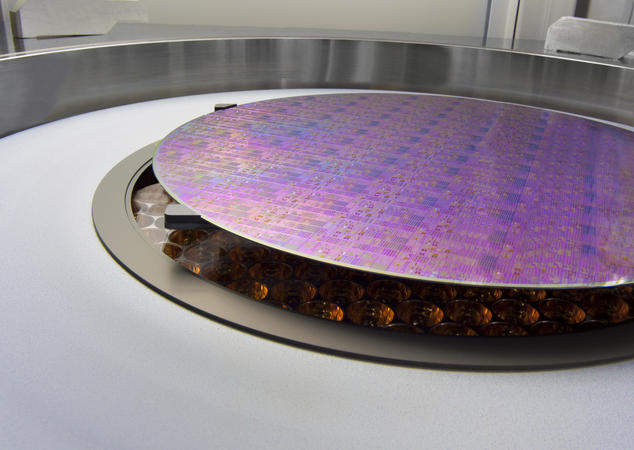

Vantage® Vulcan® RTP

A major spike annealing challenge at 32/28nm node and below is minimizing temperature differences arising from variations in radiant energy absorption within a die. This phenomenon is known as the pattern loading effect (PLE). The Vulcan system “turns technology upside down” to minimize PLE using heating lamps located below the wafer to achieve superior heating uniformity.

In addition to superior temperature uniformity, the system offers a large process range from ultra-low to ultra-high temperatures (150°C–1300°C). Thus, it combines the advanced spike capabilities of its predecessor, the Vantage Radiance™ Plus RTP system, with versatility for additional steps such as sub-second anneals, ultra-low-temperature anneals, and a wide range of metal anneals. And its “fast spike” quench improves device performance by eliminating the long cool-down periods in spike anneals that can adversely affect the fabrication of fast-performance, low-power-consumption devices. The Vulcan system continues to enable advanced scaling of junction and high-k metal gate modules.

The Vulcan system is the first lamp-based RTP platform to offer closed-loop capability at almost room temperature through transmission-based, multi-point temperature measurement for low-temperature processing, which enables superior wafer-to-wafer repeatability. Interface engineering becomes critical at advanced nodes. The Vulcan system’s lower-temperature capability helps customers optimize interface quality when diffusing nickel or more advanced materials into silicon, which facilitates scaling to thinner, better silicides with improved yields.

- 1 / 3

- 2 / 3

- 3 / 3