Products & Technologies

Products & Technologies

Services

Resources

Posted

September 16, 2022

Stay updated on our content.

Subscription Services Provide Increased Value to Chipmakers

by Jeremy Read

September 16, 2022

For chipmakers, being early to market with industry-leading technology is extremely valuable. It can directly impact market share, revenue and gross margin. The faster chipmakers can reach high-volume manufacturing, the sooner and higher the return on their fab investment. Consider this: a leading-edge logic fab requires more than $20 billion of wafer fab equipment per 100,000 wafer starts of capacity, and a leading-edge memory fab needs a bit less than $10 billion of equipment for similar volumes. Given a five-year depreciation cycle, every day is worth $5 to $10 million in depreciation costs alone.

Within Applied Materials, the group tasked with helping our customers accelerate the ramp of new process nodes to high-volume manufacturing and then maximize wafer output while maintaining the highest possible yields and optimizing costs is our services organization – Applied Global Services (AGS). On Sept. 22, Applied will host a Master Class providing an in-depth look at our services business. Several colleagues will join me to discuss the many ways AGS delivers value to our customers over the full lifecycle of process nodes and equipment ownership, and share insights into the rapid and stable growth of the subscription portion of our services business. We will also show how our services business helps make Applied a more resilient company across business cycles.

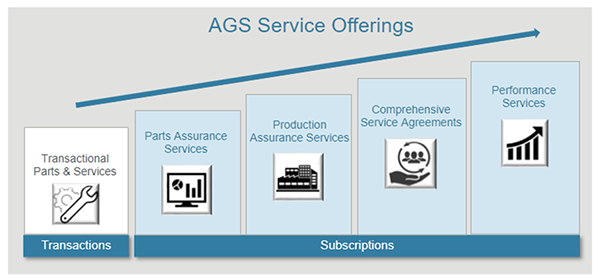

As chipmakers race to optimize power, performance, area, cost and time to market (PPACt), they are increasingly engaging AGS to achieve better outcomes and returns on their equipment investments. One way they do this is through long-term subscription agreements where Applied has a broad array of service offerings to address virtually all our customers’ needs.

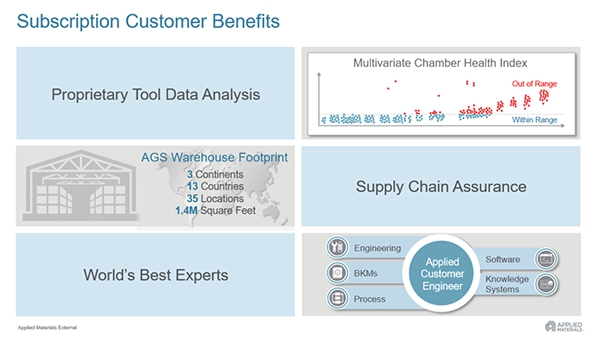

Subscription customers gain access to several benefits, including proprietary equipment data analysis, which allows us to compare a customer’s equipment performance to industry best in class. This helps them see where there is potential room for improvement in yield, output and cost. Applied has the world’s largest installed base of advanced equipment – around 42,500 systems – and we increasingly use data and analytics to understand what makes our systems perform best. We also employ proprietary technology to predict when maintenance will be needed, which reduces unscheduled downtime.

A second benefit available only to subscription customers is supply chain assurance. This service has been particularly valuable to customers during the industry supply chain challenges caused by the pandemic. In fact, even during the pandemic we have been able to serve our parts subscription customers with on-time delivery of over 99 percent thanks to measures undertaken as part of this offering.

Another benefit to subscription customers is access to our most knowledgeable equipment and fab engineers, both on-site and remotely. We can provide these experts with secure, remote connectivity to a customer’s systems and data, which speeds diagnosis and remediation. Having remote access to the world’s best experts has been particularly important during the pandemic by eliminating quarantine-related delays that would have been needed to bring our engineers on site.

Applied Materials supports our customers through more than 1,000 locations around the world, and we participate from the first R&D tool installation all the way through optimizing the highest-volume manufacturing operations. As we’ll explain in the Master Class, we work closely with our customers on their fab network expansions and help them plan factories, organize human capital, deploy digital monitoring and provide inventory support. These new kinds of engagements help our customers accelerate projects, reduce execution risk, lower working capital requirements and achieve better outcomes.

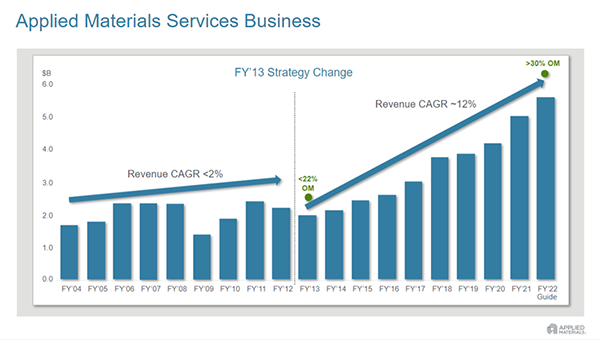

By providing increased value to our customers, AGS has become a mostly recurring revenue growth business for Applied. Since 2013, our strategy has been to transition more of our business from transactions to subscription services. Today, Applied generates about 60 percent of our recurring parts, services and software revenue from long-term subscription agreements, which has accelerated our services revenue growth CAGR to 12 percent from less than 2 percent prior to 2013. The group’s operating margin has increased from less than 22 percent in 2013 to more than 30 percent today, and our services total available market (TAM) has grown to over $14.5 billion dollars per year.

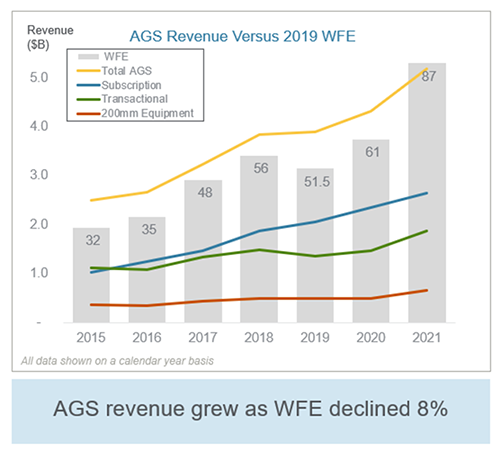

One of the main reasons AGS has become a steady growth engine for Applied is that a majority of the group’s revenue comes from recurring parts, services and software. This 87% portion of AGS revenue is correlated with wafer starts and fab utilization, rather than capacity additions. What this means is our services business can continue to grow even in years when overall industry WFE spending declines. For example, in 2019 WFE dropped by about 8 percent, driven largely by reductions in memory spending. However, AGS revenue did not decline due to the growth of the subscription portion of our business. As this experience illustrates, AGS helps make Applied Materials a more resilient company across business cycles.

Register now for the Master Class on Sept. 22 to learn even more about Applied’s services business.

Tags: Master Class, AGS Services, Subscription, chipmakers

Jeremy Read

Corporate Vice President, Applied Global Services

Jeremy Read is the head of marketing and business development for Applied Global Services (AGS). He is focused on developing value-added services that help customers improve yield. Jeremy joined Applied in 1998 as director of North American and European Sales for Consilium, an Applied company. He successfully completed the acquisition of Brooks Software and led a revolutionary software strategy for AGS that forms the foundation of Applied’s digital tools suite.

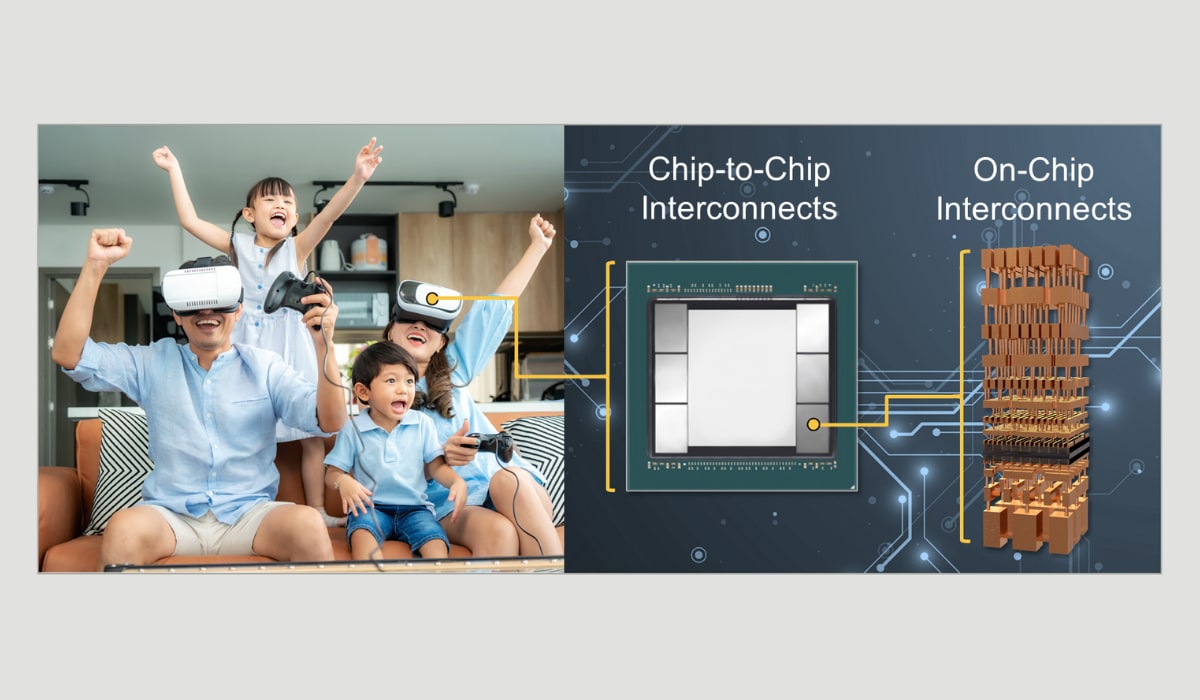

Classic Moore’s Law Scaling Challenges Demand New Ways to Wire and Integrate Chips

Ever since the earliest days of the computer industry, chip designers have had an insatiable appetite for transistors.

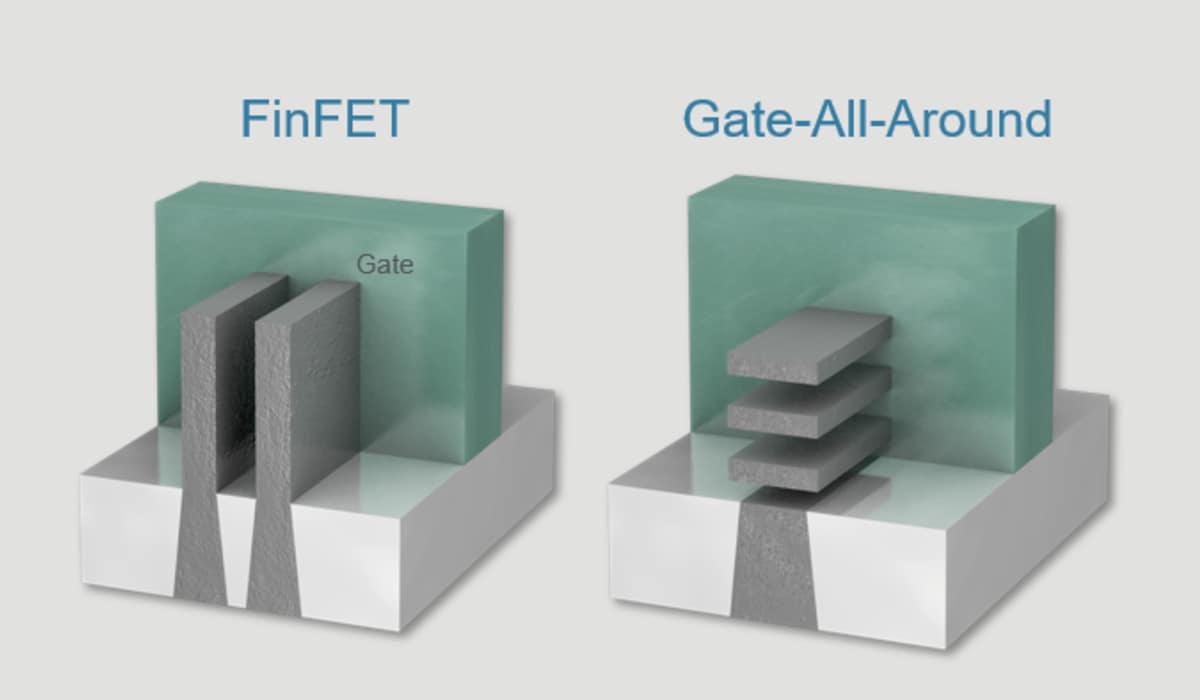

New Ways to Shrink: Further EUV Scaling Depends on Materials Engineering and Metrology Breakthroughs

Traditional Moore’s Law 2D scaling defined the chip industry’s technology roadmap for more than half a century.

Newer Ways to Shrink

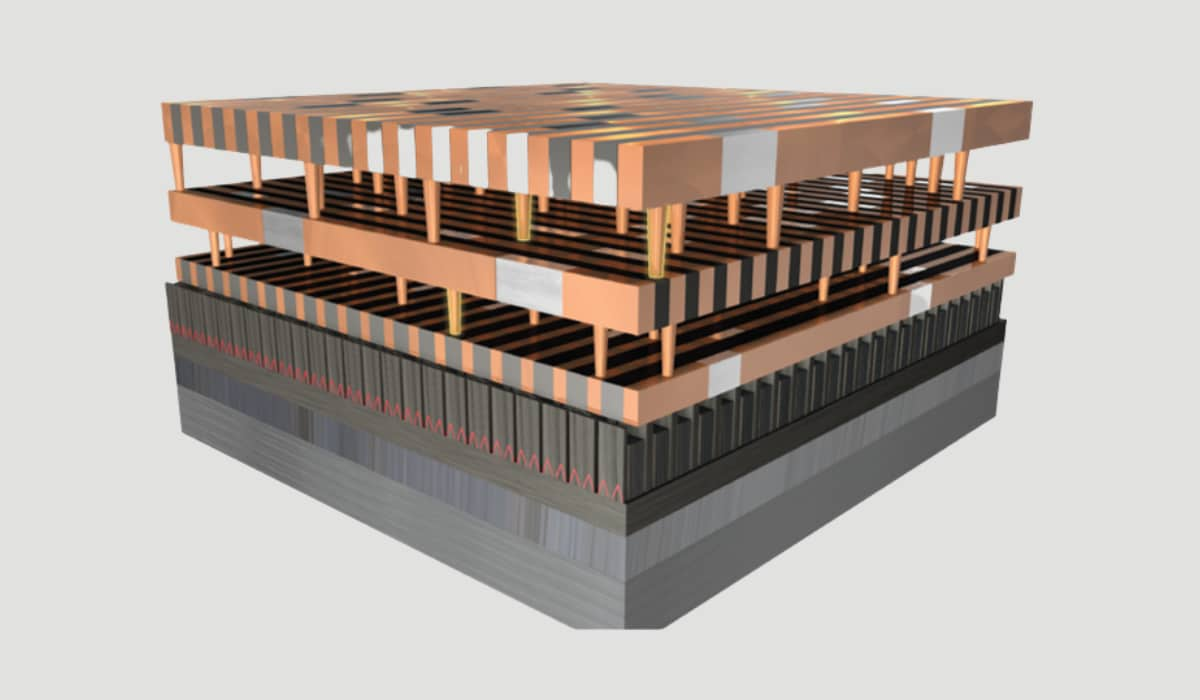

In a blog previewing our upcoming “New Ways to Shrink” Master Class, my colleague Regina Freed explained that classic 2D Moore’s Law scaling with EUV can continue well into the future—as long as we also address 6 key issues in materials engineering and metrology.