Products & Technologies

Products & Technologies

Services

Resources

Vision, Resilience and Progress

Applied Materials leads the world in manufacturing semiconductor and display equipment. At our advanced manufacturing facilities around the globe, we assemble, integrate and test various proprietary and commercial parts, components and subassemblies that are used to manufacture systems that make chips used in many of today’s electronics.

We are pioneering new ways to improve the performance, power, yield and cost of semiconductor chips using both cutting edge and mature process technologies. And we’re doing it through investments in logistics infrastructure to reduce our transportation footprint, using wind turbines to power some of our operations, and carefully managing resources and reducing waste. At Applied Materials, we build upon our expertise in semiconductor manufacturing to deliver material innovation that changes the world.

Innovation Driven Manufacturing

Our customers value us as partners who unlock the power of their ideas. Manufacturing semiconductor equipment that brings materials science to life requires creativity, ingenuity and teamwork. Our state-of-the-art innovation-driven manufacturing ecosystem leads the industry in meeting the needs of rapidly evolving end markets. Applied is making multi-billion-dollar investments to expand its global manufacturing that will enhance customer collaboration and enable us to significantly increase our capacity to meet the growing worldwide demand for semiconductors.

Precision Solutions from Creative Teams

Every day our manufacturing teams rise to the challenge of building systems that meet our customers’ needs for highly specialized solutions. The assembled systems may look similar, but the value comes in the sophisticated ways we seamlessly incorporate their many unique requirements. Our processes are always evolving as we strive to produce world-class solutions in our high-tech manufacturing environment. Our success stems from helping our customers realize their commercial potential.

Manufacturing in the Twenty-First Century

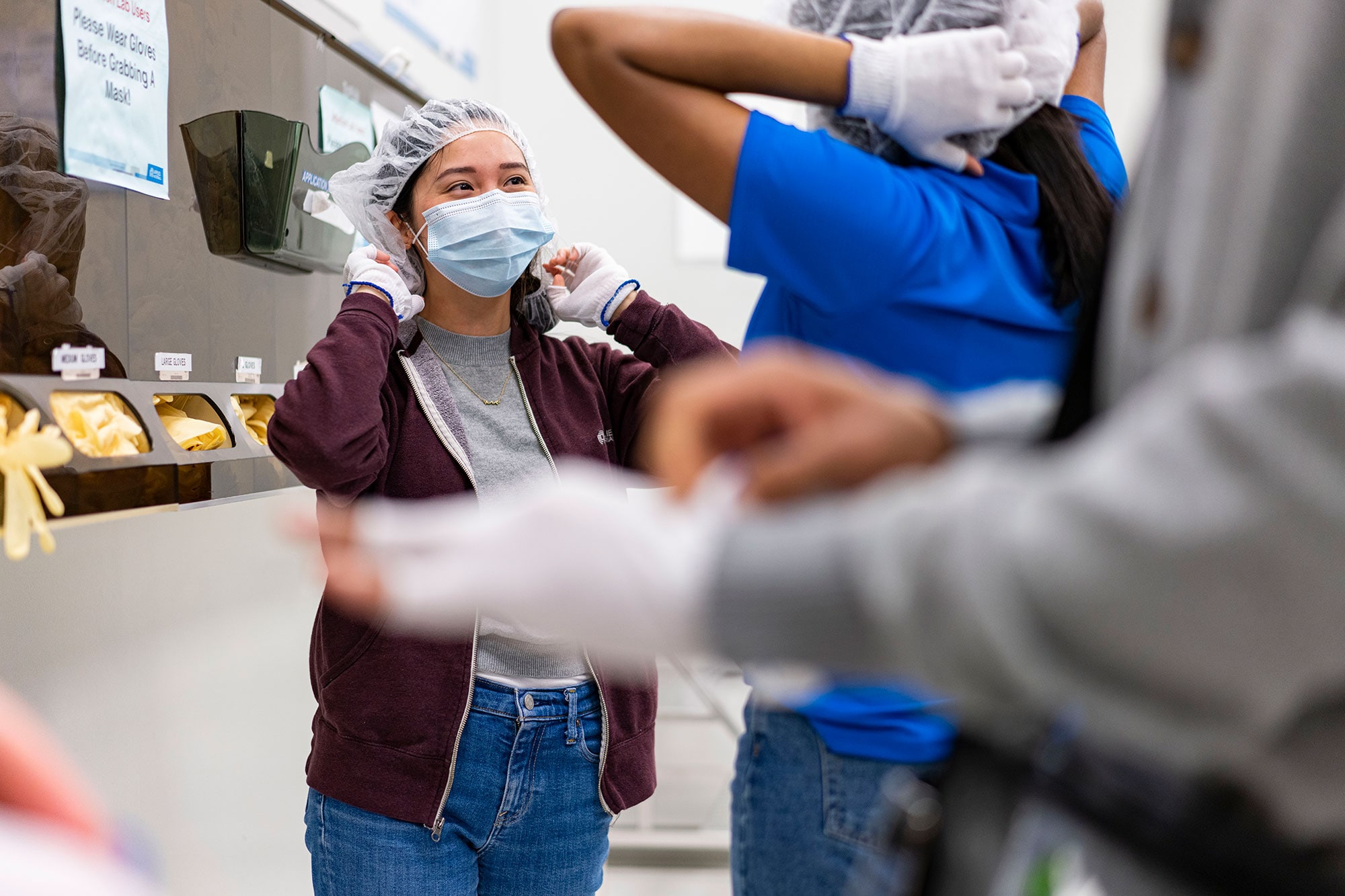

Successfully building and shipping tools to meet our customer commitments involves complex operations with many moving parts. We optimize our facilities and processes to ensure quality, efficiency, and safety. Our team values ongoing training to help us learn faster and produce results sooner.

We rely on proprietary productivity systems to ensure quality and efficiency for customers as well as safety for our people. These systems, in combination with advanced automation tools, keep us in lockstep with our logistics partners at every step of the process. Having the right parts at the right place and at the right time can be extraordinarily complicated. Our robust logistics infrastructure and use of advanced modelling and technology allow us to optimize parts delivery for our customers.

We are taking an end-to-end, data-driven approach to identify opportunities to innovate across our full network of manufacturing, logistics, and supply chain—and focusing on where we can have the greatest impact.

Interested in a manufacturing career?

A career in manufacturing at Applied provides daily opportunities to innovate and build—from using AI and VR technologies to exploring new solutions to improve manufacturing processes. Our training begins on day one and opportunities to tackle diverse, meaningful challenges are available to you throughout your career. Join us on this journey as we shape technologies that define tomorrow.

Global Presence for Local Access

We have volume manufacturing facilities in the United States, and Singapore, with additional manufacturing facilities in Germany, Israel, Italy, Korea, Taiwan and the United States.

In our labs and manufacturing facilities around the world, we have site-specific targets to help us improve our use of renewable energy, reduce water consumption, recycle, and minimize product and packaging materials.