Products & Technologies

Products & Technologies

Services

Resources

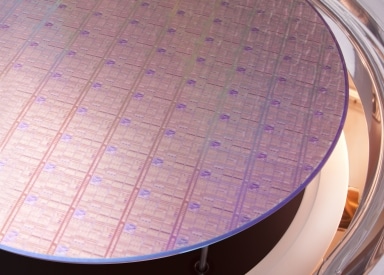

PVD

PVD is characterized by a process in which a metal vapor is generated by sputtering or evaporation of a target material that then condenses on the wafer surface. Applied has more than 25 years of experience in PVD technology development and holds undisputed market leadership in this segment.

PVD deposition processes are used to create ultra-thin, ultra-pure metallic and transition-metal nitride films for a variety of logic and memory applications in semiconductor manufacturing. The most common PVD applications are aluminum slab and bondpad metallization, titanium and titanium nitride liners, barrier deposition, and copper barrier seed deposition for interconnect metallization.

PVD film deposition requires a high-vacuum platform on which the process is integrated with degas and surface pre-treatment technologies for best interface and film quality. The Applied Materials Endura platform serves as the gold standard for PVD metallization in the industry today.