TABLE OF CONTENTS

A Letter from Ali Salehpour - Many Roads to Accelerate Time to Market

Boost Factory Productivity Faster With Applied SmartFactory™ Dispatching And Reporting

Breaking The Cycle—MtM Technologies Push Forward

In The Age of AI, Maydan Technology Center Evolves

E-Beam Review and CD Measurement Revolutionizes Display Yield Management

The Last Word: Man vs. Machine—SMEs and Learning Deeply

By David Lammers

Discussions about advanced process control (APC) often put the algorithms in the forefront and the engineer in the background. With deep learning receiving so much recent attention, people are understandably fascinated by its claimed potential to extract the value inherent in the data amassed by sensors, metrology tools and other sources. Many believe this data, if handled properly by the right deep learning tools, can help boost tool performance, improve yields, optimize wafer scheduling and more.

All true enough; though perhaps someday. But while the human element is often underappreciated, that was not true at the recent APC Conference held in Austin, Texas. This year’s conference offered an interesting balance between the potential of deep learning and the realization that technicians and engineers—often referred to as subject matter experts (SMEs)—are needed to extract its potential.

Steve Chadwick, Senior Principal Engineer, Intel

Steve Chadwick, senior principal engineer at Intel, bridged these two domains at APC 2018, describing how Intel created methods to analyze text written by Intel fab engineers and technicians. “Machines produce gobs and gobs of data,” he said, much of it structured and relatively manageable. However, “humans in general are not very structured. But what we have found is that extracting the text data is pretty valuable.”

Chadwick and several coworkers set to work creating software that would gather and parse these text-based comments. They used several open-source software and libraries (“Python is quite powerful these days,” he remarked). They took advantage of “sentiment analysis” techniques, developed largely by movie studios and the retailing industry, to analyze written comments from people who have watched movies or bought clothes.

Though Intel fab employees regularly write down their observations, it has been difficult to correlate and take advantage of those insights. In his APC 2018 presentation, Chadwick described how the same basic meaning can be written in different ways. One person writes, “The gate valve is having issues closing,” while another person notes, “There is an issue closing the gate valve.”

“We look upon our people as our most important asset. They have direct observations into the tool,” Chadwick said. But gaining value from those observations was piecemeal at best. The text analysis software had the lofty goal of “leveraging the human experience,” and the software already has saved Intel millions of dollars.

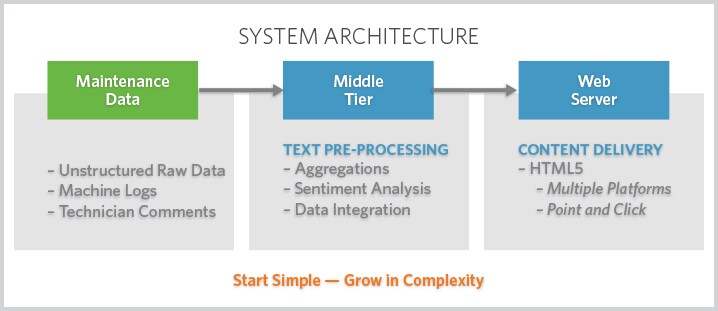

“From a system architecture standpoint, it was not that difficult,” he said. Taking unstructured raw text data, using text mining and keyword identification techniques, and adding sentiment analysis resulted in useful information. “We were surprised at how quickly sentiment analysis runs on a decent computer,” Chadwick noted.

The Intel project had one foot in machine learning to analyze words and sentiments while keeping another foot in the insights from the SMEs working in Intel’s fabs—a fascinating example of how SMEs and deep learning methods can bolster each other.

While machines generate numerical data that is easily analyzed, humans generate unstructured text data that is often valuable.(Source: APC 2018)

LOOKING FOR RELATIONSHIPS

It may seem obvious that SMEs are needed now, perhaps more than ever before, to make sense of the growing variety and size of “data lakes,” to use Chadwick’s phrase. But a naive illusion does exist (one I have been guilty of myself) that neural nets can be made to easily run practically on their own, taking unlabeled (“unstructured”) data and finding hidden correlations in those piles of numbers, metrology images and so on.

James Moyne, the University of Michigan researcher and Applied Materials consultant who helps organize the APC meetings, said deep learning techniques will find their place in the semiconductor manufacturing industry, with yield analysis being one particularly fruitful area of investigation. However he added that “for many branches of APC, such as fault detection, run-to-run control and others, statistical techniques actually work better than neural networks because they have explicit models that tell you what’s going on and allow you to incorporate subject matter expertise.”

James Moyne, PhD, Research Scientist in Mechanical Engineering, University of Michigan

PEOPLE WITH DIFFERENT SKILLS

Jim Redman, President of Consultancy, ErgoTech Systems

Moyne described a growing realization that “general SMEs” must work with “extreme SMEs” (engineers with narrow but deep skill sets) to create useful tools. When analyzing complex semiconductor processes, “the SME is not a person; it’s a team,” Moyne said.

In a tutorial at APC 2018, Jim Redman, president of consultancy ErgoTech Systems (Los Alamos, New Mexico), was bullish about the potential for deep learning to benefit the semiconductor manufacturing industry. But he also cautioned that to gain those benefits SMEs need to play a key role in instructing the deep learning tools about what relationships to look for in the data.

According to Redman, machine learning can help human SMEs by reducing “the drudgery of repetitive tasks. And for some complex tasks that are too difficult for humans, such as multivariate analysis, machine learning can perform better. There is no question that these techniques are making their way into the semiconductor industry, and they are going to make a difference.”

David Lammers is an Austin-based technology journalist.