半導體 (Semiconductor)

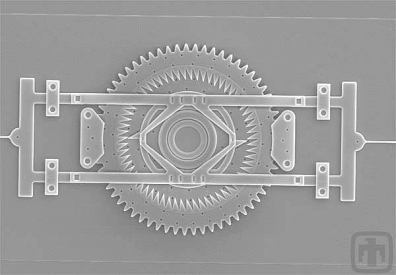

微機電系統 (MEMS)

微機電系統(簡稱MEMS)器件(包括加速度計、陀螺儀和麥克風)的使用範圍不斷擴大,目前已成為移動設備、汽車和醫療裝置市場持續轉型的主要貢獻者。隨著感測器多功能「組合包」的開發,進一步加速採行速度。MEMS器件尺寸愈小,有助於在類似的尺寸中實現更多的功能。

亟需新的材料和元件整合方案來實現這些組合包。材料包括厚磊晶層、超厚氧化物(>20μm)、氮化鋁、壓電材料(例如鋯鈦酸鉛)和低溫CMOS相容薄膜,如矽鍺。整合則包括新的封裝製程,如 TSV,可加速元件堆疊。

由於大部分MEMS市場成長來自消費類裝置的推波助瀾,上市時間和成本是MEMS製造商面臨的重大挑戰,同時高生產力、高良率生產機台的需求與日俱增。有鑒於此,應用材料公司正運用我們經過生產驗證的平台,開發新的200mm功能,以迎接MEMS市場龐大需求與技術挑戰。