Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

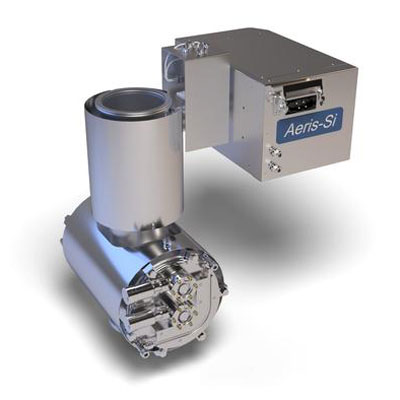

Aeris®-Si

Aeris-Si is an integrated solution for subfab foreline cleaning to manage silica load and improve pump lifetime. The solution enables a high flow tetraethyl orthosilicate (TEOS) process for the highest deposition rate and throughput, while extending pump lifetime from 1 to 12 or more months resulting in less than a 1-year ROI. The system has no impact on wafer qualification data due to foreline plasma during cleans, and all process parameters operate within normal ranges.

The Aeris-Si process collects SiO2 powder prior to the pump inlet. By using NF3 plasma technology, the system converts the solid silica particles to pump-friendly SiF4 gas, thus preventing the build-up of solids inside the pump.

Features

- Proprietary trap design for solids accumulation during deposition and solids removal during chamber clean

- Particle accumulation reduced in foreline and pump by converting solid Si02 into gaseous SiF4

- Tool interface for smart operation

- Data collection and reporting—can be interfaced to customer monitoring systems

Benefits

- Extends pump lifetime from 1 to >10 months for high flow TEOS systems

- Offers lowest downtime and maintenance costs of foreline and pumps

- Provides >7% uptime improvement

- Enables highest improvement of overall wafer yield at deposition stage

- Enables highest throughput for high flow and TEOS process (18G/min/side)

- Fits easily into existing exhaust lines, requiring only power, cooling water and clean gas connections

- Achieves ROI within 8 months