熱門話題

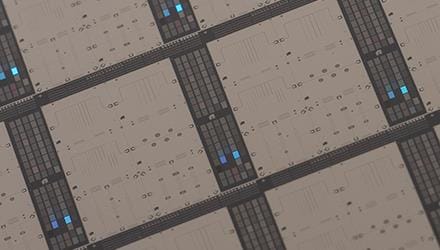

Co-optimized Process and Metrology Accelerates Molybdenum Contact Development

Applied Materials Hosts Lively Debate on AI Energy Efficiency

A Quantum Leap: Celebrating Dr. John Martinis and the Future of Computing

Jensen Huang in Conversation with Gary Dickerson on the Evolution of AI