Products & Technologies

Products & Technologies

Services

Resources

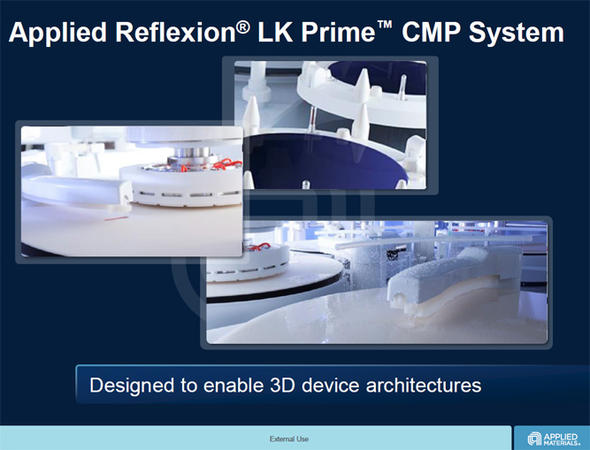

Reflexion® LK Prime® CMP

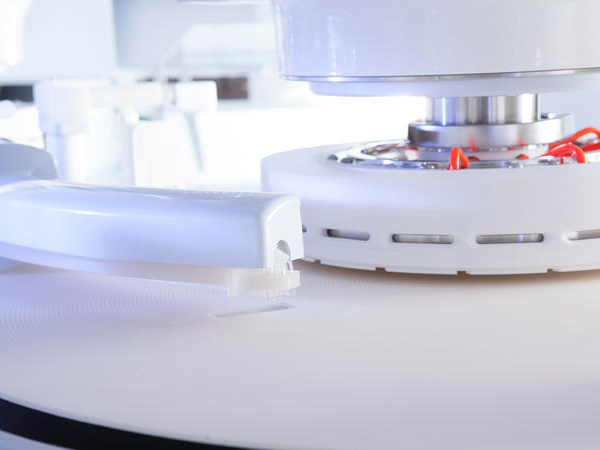

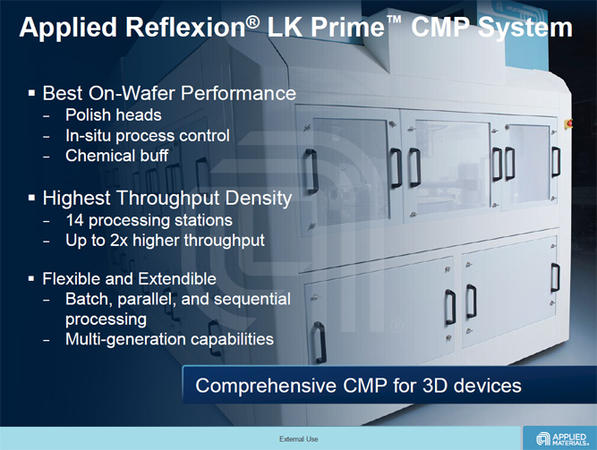

Featuring sequential processing stations using four polishing pads, six polishing heads, eight cleaning chambers, and two drying chambers with advanced process controls, the Reflexion LK Prime CMP system delivers precision processing and high productivity for today’s most advanced CMP applications. The Reflexion LK Prime CMP is optimized for two-step CMP applications, while maintaining the performance of the Reflexion LK CMP. Its greater polishing and cleaning capacity (14 vs. 7 modules on the Reflexion LK CMP), and optimized wafer handling make possible up to double previous wafer throughputs for many applications, resulting in up to a 100 percent improvement in productivity.

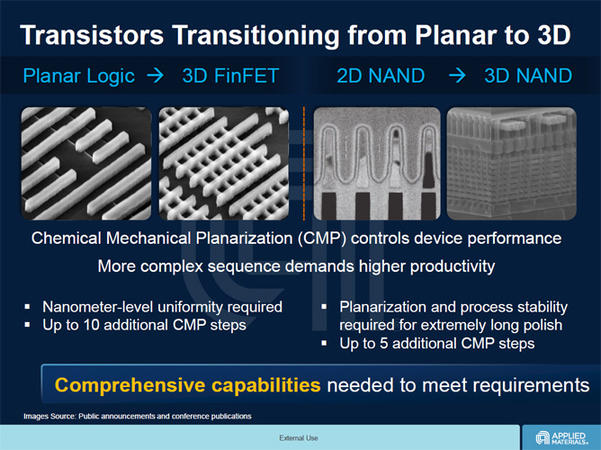

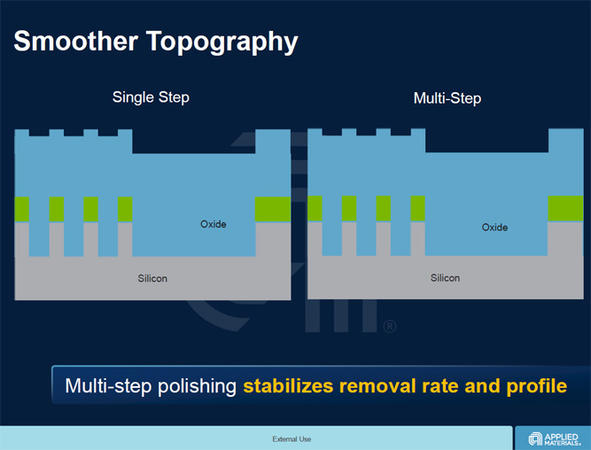

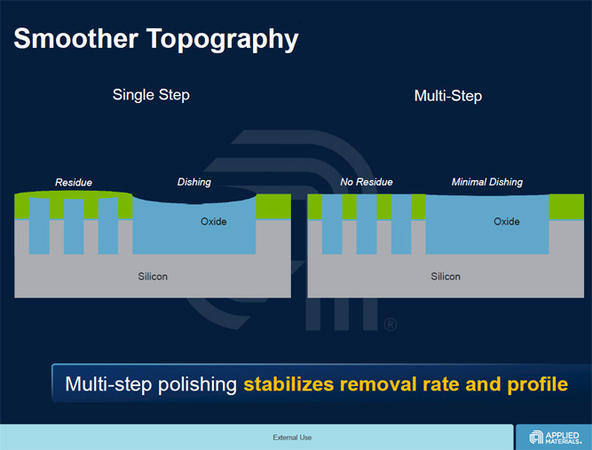

The capability to use each polish and cleaning station independently enables flexibility to run sequential, parallel, or batch processes as well as a greater degree of customization on each platen. For example, the thicker film layers and broad topography of 3D NAND need long, steady polishes. Executing these as a series of shorter polishes over multiple platens enables stable, predictable planarization. This in turn helps to optimize on-wafer performance and reduce defects. As with the Reflexion LK CMP system, the LK Prime system also employs the latest polishing, cleaning, and process control technologies to ensure the highest levels of performance in meeting future device node requirements.

- 1 / 8

- 2 / 8

- 3 / 8

- 4 / 8

- 5 / 8

- 6 / 8

- 7 / 8

- 8 / 8