Products & Technologies

Products & Technologies

Services

Resources

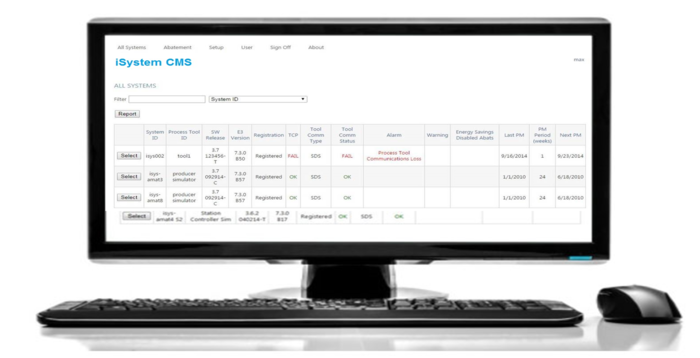

iSystem® Controller

While monitoring tool operation, the Applied iSystem controller collects valuable data that can be used to generate resource consumption reports and greenhouse gas emissions reports among other environmental factors. Each small footprint iSystem controller is capable of supporting up to four tools and is easily installed on both Applied and non-Applied Materials 200mm and 300mm process tools. With more than 3000 tool connections currently installed, manufacturers have reported rapid ROI after using the iSystem controller.

Features

Easy installation in new and existing fabs

Configurable at tool or subfab level

Fail-safe safety protocol

True fab and subfab synchronization

Intelligent idle mode

Supports Semi E167 and E175 standards for Sleep Mode

Subfab data collection, alarm monitoring, notifications and reporting

Subfab status visibility from a single monitor

Applied E3 and FSS data server support for complete fab/subfab data analysis

Benefits

Reduces energy-related costs by ~20%

Connects to process tools in real-time

Enables green features with no equipment changes or process re-qualification needed

Provides continuous greenhouse gas emissions reporting

Enables fab/subfab data integration and overlay

Recovers from idle to process state fuel flow in <2 seconds